A circular economy, geared towards minimizing waste and maximizing natural resources, hinges on reusing, repairing, remanufacturing, and recycling products and materials. It establishes a closed loop that conserves natural resources and facilitates the regeneration of natural systems. In sharp contrast to a traditional linear economy, where products are made, used, and then discarded, circularity is imperative for a sustainable future.

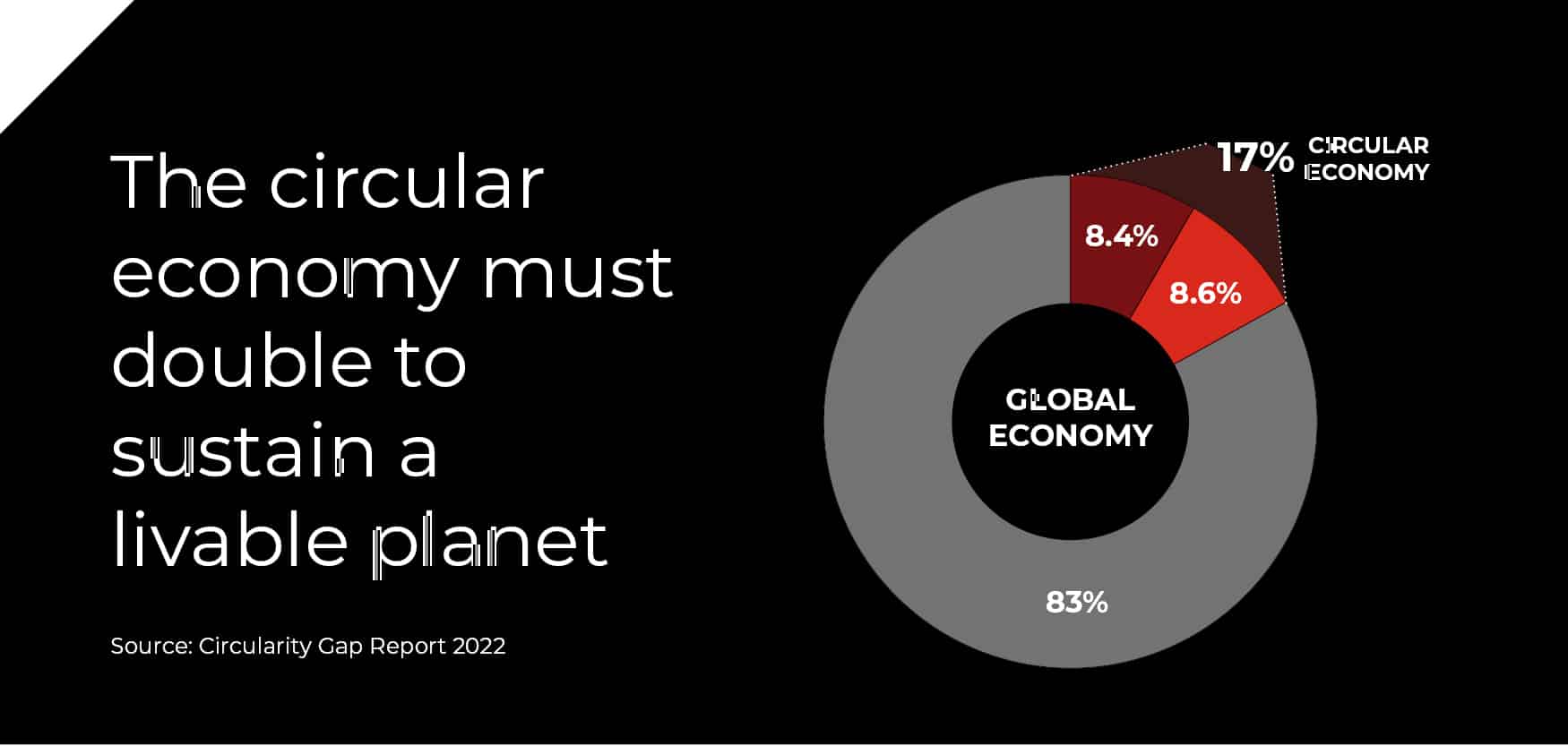

The built environment presently accounts for a staggering 40% of material use by mass and 50% of material waste by volume. Crucially, it is the primary end-use for high-impact materials cement, iron, steel, and aluminum. Recognizing that the global economy must double from 8.6% circular (as it currently stands) to at least 17% circular to sustain a livable planet, it becomes imperative for our industry to adopt a more circular approach. The incorporation of circular practices, particularly in the specification of products, empowers architects and engineers with the means to significantly diminish the environmental impact of our industry on the planet.

I recently had the privilege of moderating a panel, “The Circular Built Economy,” organized by AIA Connecticut’s Women in Architecture Committee. This engaging discussion identified how material and product selection impacts the circularity of a building, how material ingredients impact the circularity of a product, and how upcoming regulations and updated standards related to circularity will affect architects and designers. Some key takeaways that can guide architects and engineers towards actionable steps to join and improve the circular economy include:

- Circular Material Selection Powers Sustainable Design

A circular economy is integral to sustainable design, constituting a significant piece of the puzzle. While reducing operational greenhouse emissions is crucial, reusing materials is equally vital. Architects and engineers play a pivotal role in achieving this goal by consciously selecting circular materials.

- Regulatory Bodies Enable Circular Identification

Architects and engineers navigate the circular landscape with the guidance of regulatory bodies such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These bodies certify products, providing assurance that materials are circular. Advancing and enforcing these standards ensures that our choices align with circular principles.

- Measurement Tools Shape Circular Choices

Programs like Cradle to Cradle set the global standard for circular materials, products, and systems. This certification aids architects and engineers in selecting products that positively impact both people and the planet. By embracing these tools, we contribute to the shift towards a circular economy.

- Early Collaboration Enhances Circularity

Architects and engineers can catalyze circular practices by including product suppliers and contractors early in the design process. This collaboration allows for expert insights into circular products and construction methods. Initiating a dialogue with suppliers about their sustainability plans stimulates them to delve into their materials’ sustainability metrics and empowers architects to make informed choices. This proactive engagement signals architects’ genuine interest in understanding and influencing the circularity of the materials they specify.

While reducing operational greenhouse emissions is crucial, reusing materials is equally vital. Architects and engineers play a pivotal role in achieving this goal by consciously selecting circular materials.

At STV, we’ve long been committed to sustainable and resilient design. Our approach recognizes sustainability as protecting the environment from infrastructure by reducing our human footprint. On the flipside, we view resilience as protecting infrastructure from the environment by enhancing our designs to withstand ever-evolving climate conditions. Both concepts benefit from optimizing material consumption, incorporating nature-based solutions, and preserving natural resources.

Our commitment manifests in projects such as the City of Costa Mesa’s Donald Dungan Library & Norma Hertzog Community Center. By investigating innovative material reuse options, STV was able to minimize waste and repurpose demolition materials for the new library’s foundation. Similar efforts were undertaken at the Massachusetts Bay Transportation Authority’s (MBTA) Hingham Intermodal Center, where STV’s design included the use of recycled, regional, and rapidly renewable materials for the building’s interior and exterior finishes. At the Washington Metropolitan Area Transit Authority’s (WMATA) Greenbelt Test Track and Commissioning Facility, STV specified the widespread use of locally produced, recycled building materials, with half of the wood products being Forest Stewardship Council certified.

As part of our journey towards a circular economy, STV signed the Structural Engineers 2050 Commitment (SE 2050) and proudly submitted our first annual Embodied Carbon Action Plan (ECAP) in 2023. With a focus on reducing our embodied carbon footprint through sustainable material choices and data-driven design, our ECAP pledges to incorporate sustainability-driven specification guidance, identify opportunities to implement low-carbon materials and maintain a robust embodied carbon educational program, among other commitments.

To delve deeper into the transformative journey toward circularity, watch AIA Connecticut’s panel discussion here.