STV, as engineer-of-record for the E-J Electric design-build team, recently completed the design for maintenance facility upgrades at the 270,000-square-foot Gun Hill Bus Depot in the Bronx, NY. This project will add charging infrastructure for 73 battery-electric buses (BEBs), advancing New York City Transit’s goal of converting its fleet to zero-emission vehicles by 2040.

As lead designer and engineer-of-record, STV is partnering with E-J Electric on this design-build project on behalf of the New York Power Authority and Guth DeConzo Construction Management, Inc. The STV team provided comprehensive structural, electrical power, charging and communications design.

STV delivered the 100% final design documents in December, meeting an aggressive seven-month schedule to issue drawings for construction. The team has been engaged in construction support since January 2025, with the project’s construction on track for completion this fall.

“Our strong design-build collaboration has been essential throughout this project,” said Daniel Arbelaez, RA, LEED AP, Assoc. DBIA, architectural director at STV. “From developing innovative ideas together during the proposal phase to refining them into the final design package, constant collaboration between STV and E-J Electric ensured every detail aligned with the construction schedule and constructability needs.”

The project introduces overhead pantograph charging infrastructure for 55 40-foot and 18 65-foot buses. The pantograph system inside the facility will be powered by 37 chargers mounted on the depot’s roof. Adapting an existing facility posed significant challenges, requiring selective removal and relocation of existing equipment to accommodate the new charging system.

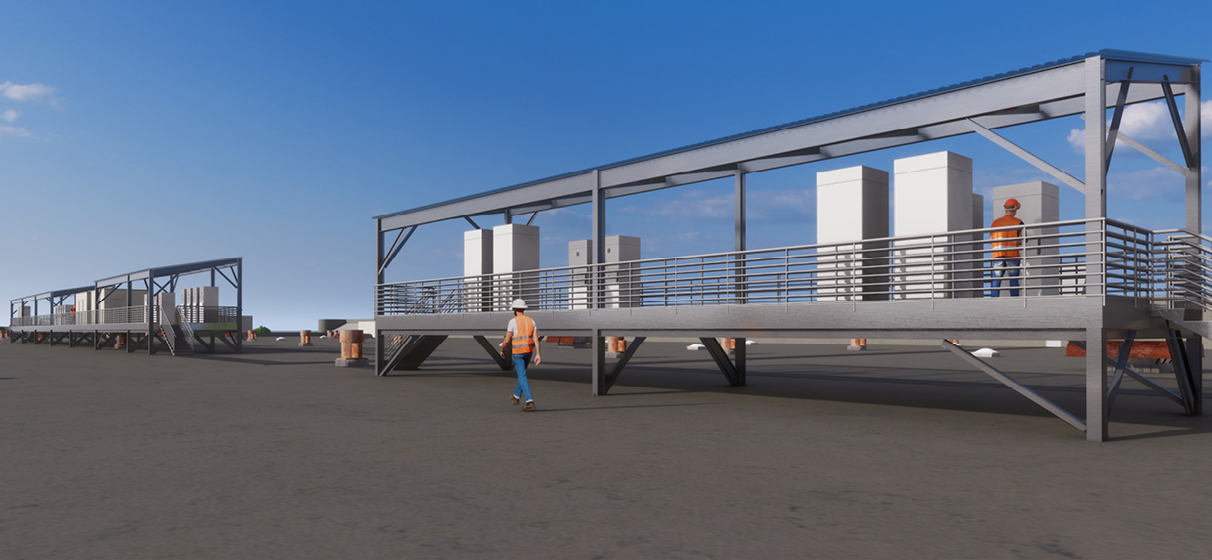

To minimize roof penetrations and preserve the existing membrane roofing warranty, STV designed raised steel-framed dunnage platforms to support the roof-mounted charging cabinets and conduit. Our team also consolidated conduit penetrations into fewer, larger openings with integral curbs, simplifying flashing details. Elevating the equipment improved access for conduit connections. Additionally, the design incorporated a prefabricated high-voltage switchgear e-house, delivering 480 V, 60 Hz power to the 37 chargers.

“The charging infrastructure at Gun Hill required unique positioning of rooftop chargers to limit the power cable distance to 250 feet,” said Mark Griffiths, PE, engineering chief at STV. “We proposed a rooftop platform to group chargers in alignment with bus positions below, as well as a pre-engineered roof penetration system to consolidate conduit routes. The original RFP called for multiple roof penetrations, which would have resulted in longer rooftop conduit and cable runs. By optimizing the electrical layout on a shared platform, we reduced conduit and cable requirements, generating considerable cost savings for the contractor.”

Accommodating this new infrastructure within the existing depot required close coordination between STV’s structural and charging infrastructure design teams. With only 14 feet of clearance from the existing roof trusses, headroom for additional structural framing was limited. STV designed new framing to support the pantographs at the correct height while maintaining ample space around them to ensure accessibility for maintenance. To minimize modifications to the existing structure, the new steel framing connections utilize beam clamps, reducing the need for field welding or drilling.

“The structural design had to balance efficiency with adaptability,” said Tom Lisofsky, PE, SE, structural engineer at STV. “By carefully coordinating new framing with existing conditions, we provided robust support for the charging infrastructure while minimizing impacts on the facility’s operations.”

To meet the fast-track construction schedule, STV worked closely with the contractor to release early construction packages, including the prefabricated switchgear e-house. The team defined requirements as early as the 60% design phase to expedite procurement.

“STV and E-J Electric combined their expertise to bring fresh perspectives and innovative solutions to the project,” said Jose Vasquez, electrical engineering specialist at STV. “Each team contributed unique strengths, whether in creative problem-solving or specialized technical knowledge. Clear communication and shared goals ensured an efficient process, driving success beyond what either team could have achieved alone.”