The Hudson River Ground Stabilization (HRGS) Project helps create the path for the larger Gateway Program Hudson River Tunnel between New Jersey and New York. Currently underway along the Manhattan side of the Hudson River, this early element of construction encapsulates just how much progress we’ve made on Gateway in a short amount of time.

In my capacity as Senior Project Director for the Gateway Trans-Hudson Partnership, the consortium of consultants including STV that is helping deliver the project, I recently had an opportunity to get an up-close view of the HRGS Project. It was an experience that really gives an impressive sense of the overall scale and scope of the Gateway Program.

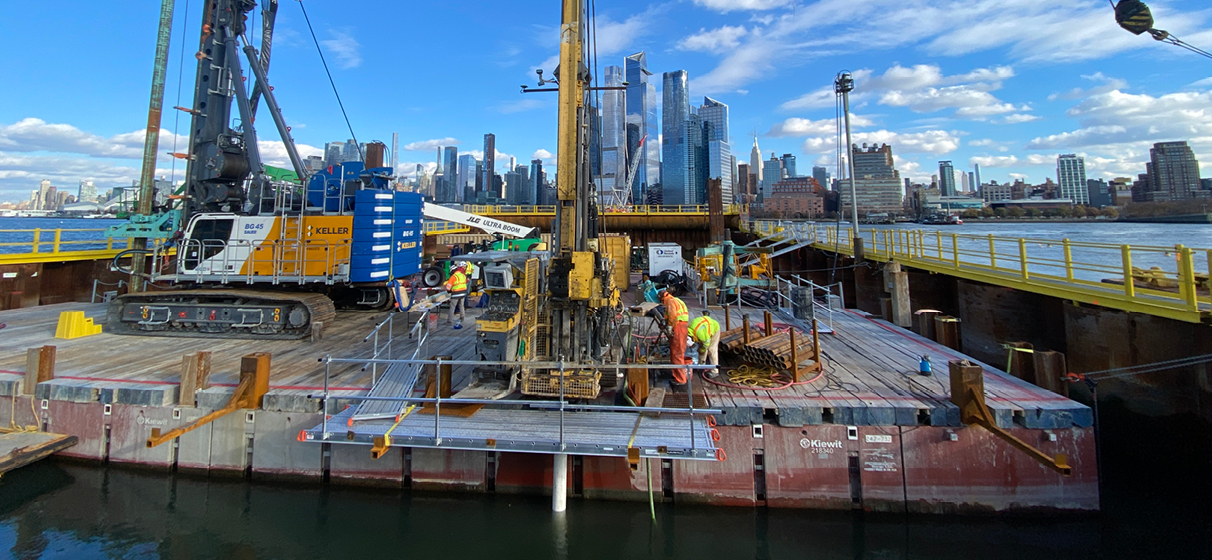

The HRGS Project involves injecting cementitious material into the silt that makes up 1,200 feet of shallow riverbed along the Hudson River in order to create columns of soil mixed with cement and water. In doing this, the construction team is creating a block of reinforced earth that is strong enough for the tunnel boring machines (TBMs) to pass through the soft material of the existing river bottom while also minimizing impacts to the river’s ecosystem.

This work is one of the first pieces of heavy construction work since the Gateway Program’s Hudson Tunnel Project first broke ground about a year ago. Phase One of HRGS includes the design and construction of a test cofferdam, bathymetric and geophysical surveying, identification and removal of obstructions and the completion of a demonstration testing program. Phase Two will use these findings to complete construction.

STV, in joint venture, is currently serving as the designer-of-record for the Gateway Program Hudson River Tunnel by constructing a new two-track tunnel under the Hudson River, thereby facilitating the rehabilitation of the North River Tunnel, which sustained severe damage during Superstorm Sandy in 2012. Our team is also providing program management support, risk management, procurement assistance and technical assistance services.

After seeing HRGS progress firsthand, what really comes into the view is the scale and challenges associated with this early element of the Gateway Program. The construction footprint of HRGS is 1,200 feet long by 100 feet wide and resembles a shoebox in the vast Hudson River. And yet within this “shoebox,” essential work is being done for this transformative infrastructure program. Construction crews are currently creating 8-foot-wide columns below the riverbed, which will provide the runway for the TBMs to pass through and create the tunnel.

Much of the alignment for the future Gateway tunnel will pass through solid continuous rock. Through the eastern end of the tunnel alignment (i.e. closer to Manhattan), a lot of the hard rock falls away and you’re left with soft, unstable river silt. TBMs can not operate effectively in such unstable ground conditions and the HRGS will address that concern.

While working in the Hudson River, the project must comply with state and federal environmental restrictions that mandate that construction activities outside of the cofferdam can only take place during certain times of year. That’s why the HRGS Project is divided into phases, and is expected to be complete in 2027.

Still, the complexities of the project pale in comparison to the overall excitement the entire team shares as we hit one milestone after the next. For years we talked about the need for Gateway. We’re now firmly on our way on delivering it.