Recent incidents, such as the collapse of Maryland’s Francis Scott Key Bridge earlier this year, have underscored the need to identify strategies to better protect bridge infrastructure from vessel collisions. As larger ships navigate our ports and waterways with increasing frequency, these structures are under unprecedented pressure, making bridge safety an essential focus for infrastructure owners and consultants alike.

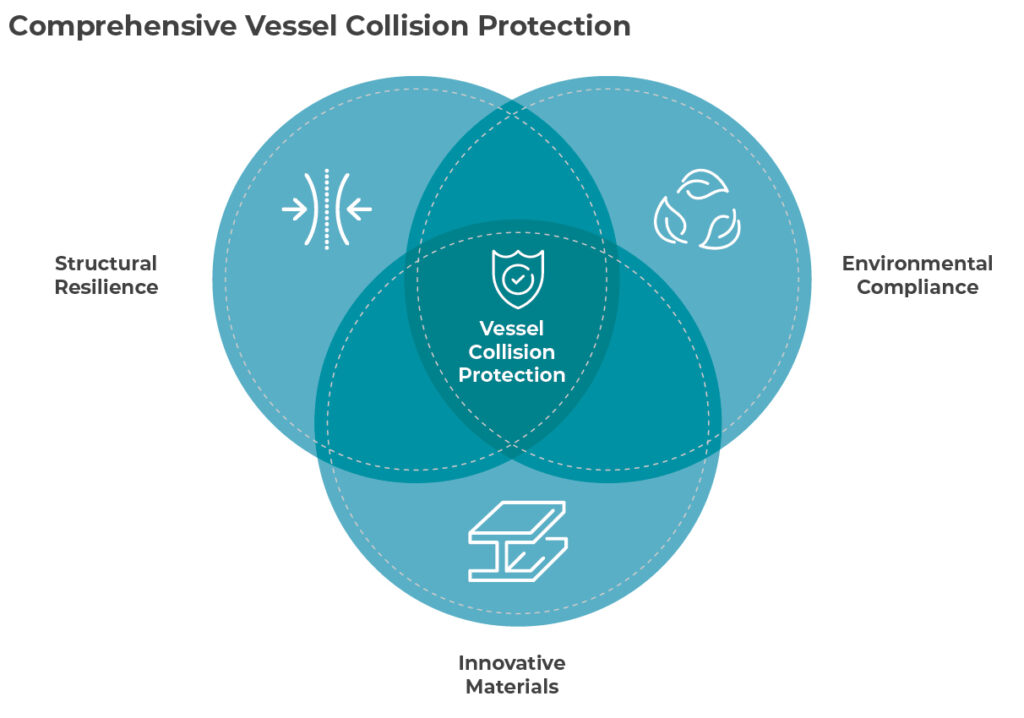

At STV, our approach to vessel collision protection involves a careful blend of structural resilience, environmental compliance and the use of innovative materials. A recent project exemplifying this approach is the Fore River Bridge Replacement in Boston. Given the area’s busy channel and Panamax-class vessel traffic, our team engineered a robust fender system that balances high-capacity vessel protection that complies with evolving U.S. Coast Guard (USCG) standards.

This project features a 2,640-foot-long movable bridge with a 324-foot lift span, designed to endure the scale of Panamax ships while maintaining robust safety features. The bridge, featuring four vehicle lanes, two bicycle lanes and ADA-compliant sidewalks, improves accessibility and operational efficiency. Critical to its vessel protection capability is a sophisticated fender system integrating concrete and steel components to withstand intense tidal changes and currents. By advancing the bridge’s lift design to 60% and its approach spans to 30% for the design-build procurement phase, the project team established a new standard for comprehensive, resilient fender systems.

Similarly, for the Outerbridge Crossing (OBX) Fender Replacement in New Jersey, our team designed the replacement of outdated cellular cofferdams with a robust pier protection system designed to shield the structure from the impact of Panamax vessels. This project presented unique challenges, requiring extensive adjustments to meet evolving security standards while navigating complex permitting issues.

During the design process, STV analyzed the bridge piers for both vessel collision and blast resistance, adhering to the stringent standards required for high-traffic, secure waterways. When permitting requirements called for modifications to channel clearance procedures, the project transitioned to a fender system with a reduced capacity, deemed acceptable for protecting the substructure from unexpected vessel impacts. Despite this change in scope, the OBX project reflects the adaptability required to protect vulnerable infrastructure in complex environments.

When dealing with more historic infrastructure, there are some unique design and construction challenges to consider. For the Belden G. Bly Drawbridge in Massachusetts, which was originally built in 1913 and is one of the oldest Scherzer Rolling Lift bridges in the country, STV team’s design balances historic preservation with modern resilience.

A key element of this project is a conventionally detailed fender system, equipped to handle the specific vessel design loads of the local fishing fleet. The team utilized durable materials like fiberglass and concrete-filled piles to enhance longevity, along with plastic composite-reinforced walers for added ductility and flexibility. The Belden G. Bly bridge program highlights how detailed considerations of material properties, such as the plastic walers’ increased deflection capabilities, can add strength and longevity to fender systems while addressing specific local needs.

Each of these projects reinforces the importance of vessel collision protection in the face of evolving infrastructure challenges. For bridge owners, understanding risk tolerance—knowing the acceptable level of potential damage—is essential in defining a structure’s protection requirements.

Moving forward, as America’s ports handle larger vessels and higher traffic volumes, identifying and protecting economically critical infrastructure will become mandatory in the field. By learning from recent and historical infrastructure challenges, we continue to build a more resilient and adaptable approach to bridge engineering that strives for safety and endurance across the nation’s waterways.