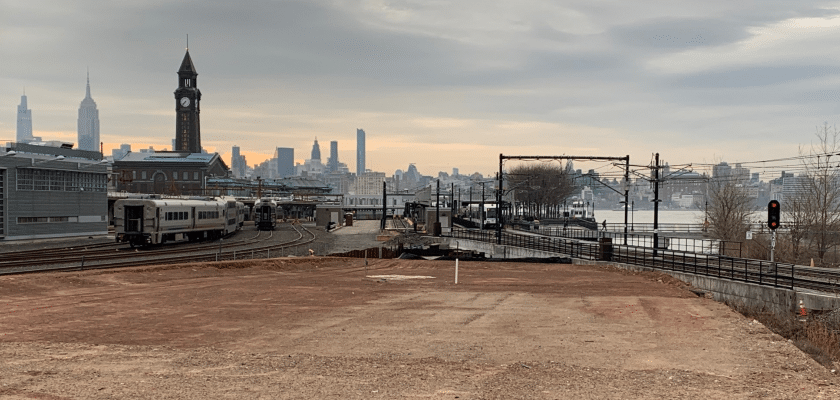

For over a century, the Long Slip canal connected the nation’s rail lines to New York City. Adjacent to Hoboken Terminal in New Jersey, the canal ferried freight barges that carried cargo across the Hudson River into Manhattan. But for the past 50 years, it sat inactive.

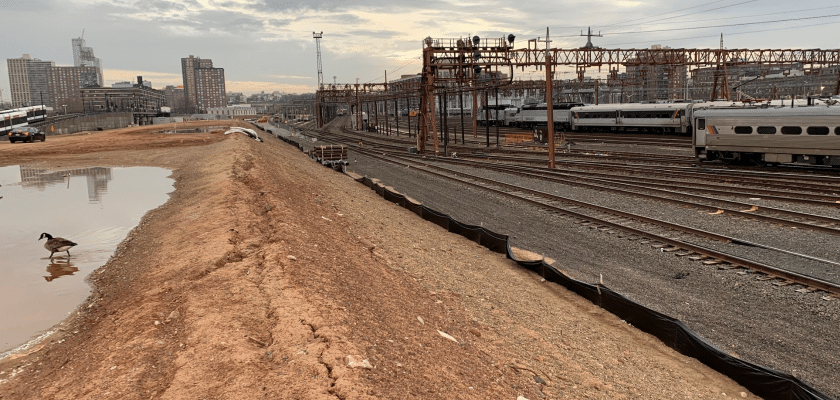

Now, the canal has been filled, preparing for its new role as the site for NJ TRANSIT’s expanded rail service. STV is providing construction management services for Phase 1 and Phase 2 of the NJ TRANSIT’s Long Slip Fill and Rail Enhancement project—a key part of the agency’s Superstorm Sandy Resilience Plan.

In 2012, Superstorm Sandy caused the canal to overflow and flood the Terminal and Hoboken Yard, resulting in destructive damage that impacted service for months. NJ TRANSIT (NJT) embarked on an extensive Sandy Resilience program to fortify a sustainable transit system across New Jersey.

At the Hoboken Terminal – where STV previously served as NJ TRANSIT’s project manager for the historic facility’s redevelopment and rehabilitation – three new elevated ADA-accessible boarding platforms, six tracks, and a station/crew facility will be built atop the filled canal. This new, integral transit infrastructure will not only protect the historic structure from flooding but will also maintain service for the thousands of commuters who travel through the terminal daily.

While filling a canal sounds like a simple enough task, the Long Slip canal at Hoboken Terminal was one the most geotechnically unique projects that our team has encountered.

First, its location presented a few challenges, as the site sits directly between the Hudson-Bergen light rail system and the NJT commuter rail tracks. Directly underneath the canal are two PATH tunnels, operated by the Port Authority of New York and New Jersey, that are so sensitive that vibrations caused by construction could potentially shut down service.

“Maintaining rail operations throughout construction was paramount, for our team, NJ TRANSIT, and the Port Authority,” said Mike Moskowitz, STV’s construction manager for the project. “To not disrupt the light rail and commuter rail, we conducted most of the construction from a barge floating in the 100-foot-wide canal, which was made specifically for this project. We also oversaw the installation of movement monitoring equipment in the PATH tunnels that transmitted movement signals in real-time, ensuring that the tunnels and PATH trains were safe.”

The team also ran into a unique geotechnical phenomenon, known as a mud wave, while excavating the canal. Dating back to when the Long Slip canal was first constructed more than 100 years ago, the bottom was filled with sewage effluent and organic materials that mixed with naturally occurring mud. Our team was tasked with excavating the muck, installing large culverts, and extending the discharge point for Jersey City’s combined sewer overflow. The CSO’s discharge point previously terminated at the west end of the Long Slip, letting sewage and runoff from Jersey City build-up within the canal’s water and floor for decades.

Our team managed the installation of the 10-foot by 12-foot culvert sections, constructed in the dry underneath the canal water, and extended the CSO by 1,800 feet. This multidisciplinary process involved the CSO installation via cofferdam construction, with periodic inspection and underwater dives to monitor the process.

Though the initial contract factored in the removal of the highly compressible, organic materials, the volume of the environmentally sensitive mud was unexpected.

While adding surcharge fill to the bottom of the excavated canal, the mud rose up and pushed through previously applied lifts of the clean surcharge fill material and as well as Geotech filter fabric liner that was applied between the excavated floor and the fill. Because the canal is at a lower elevation compared to the New York Bay, hydraulic pressure differences between the two caused the mud to bubble up.

“Our team quickly analyzed the phenomenon, alongside NJT personnel and the rest of the team,” Moskowitz said. “We then coordinated with the geotechnical engineer of record for the project and managed a revised mixture of clean fill with strategically designed portions of surcharge fill, reducing the amount of purchased, clean fill required. This resulted in substantial cost and schedule savings for our client.”

The team oversaw the installation of hundreds of wick drains that soak up water from the surcharge through capillary action, almost like a sponge. This rarely used technique squeezes any water out of the surcharge fill, compressing it so that the bottom of the fill becomes solid. The team is currently monitoring the consolidation process to determine when sufficient consolidation is complete. Once consolidated, the surcharge will be removed, flattened, and prepared for Phase 2 of the project, adding 4.3 acres of new land to the NJT complex.

“STV’s long history of partnering with NJ TRANSIT at Hoboken and throughout the state, our collaboration with the Port Authority, and our geotechnical expertise all contributed to the project’s success. We’re excited to be part of this vital project that supports the agency’s broader Sandy Resilience program,” Moskowitz said.